|

|

|

|

|

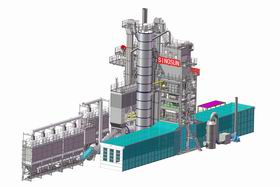

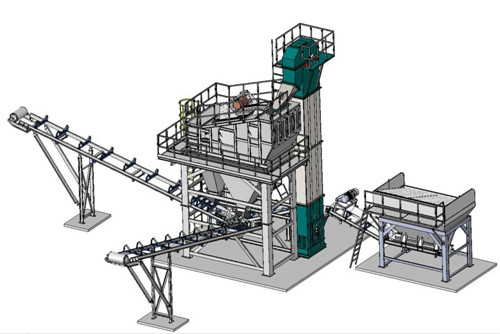

Advantages: 1. Increase the proportion of reclaimed materials, reduce the consumption and production cost. 2. Effectively reduce the degree o f asphalt aging, reduce greenhouse gases, such as asphalt smoke emissions, improve the working environment. 3. Prolong the service life of asphalt mixing equipment, reduce the equipment operation cost. 4. Adapt to a validity of working conditions, especially in low temperature construction of long and large tunnel construction. 5. Each technical performance meet to the requirement of construction standard, increase the workability of asphalt and stone. |

|

|

Philippines:17F High Street South Corporate Plaza Tower 2, 26thStreet cor. 11th Ave, BGC, Taguig

TEL: +63 908 868 1506

Email: eagloballbuilders@gmail.com

Singapore:60 Paya Lebar Road, #12-03, Paya Lebar Square, Singapore 409051

Thailand: 948/22 Rama 2 Rd, Mahachai Samutsakon 74000

TEL: +0642 85 2984

Iran: Tehran, Vanak, Sheikh Bahaei square, Sadaf Tower, No.47

TEL:+86-13523776367

FAX:+86-371-55007709